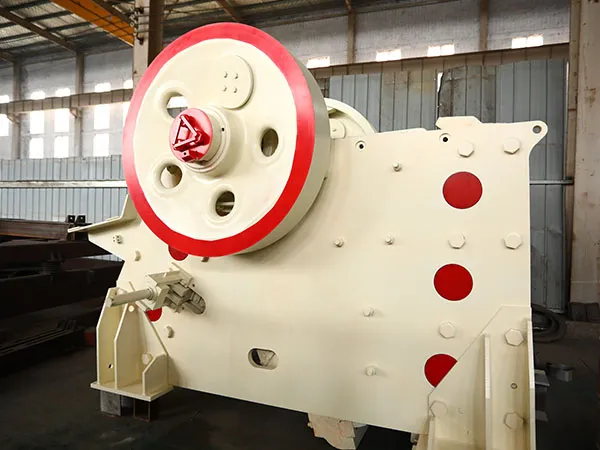

A jaw crusher's particle size range depends on the specific machine's design and settings. Generally, a jaw crusher is a primary crusher, meaning it's used for the first stage of size reduction. They can handle very large feed material and produce a coarse product. The output size is primarily determined by the closed-side setting (CSS), the minimum distance between the jaws.

Typically, jaw crushers have a reduction ratio of 6:1 to 8:1, meaning the output size is approximately one-sixth to one-eighth of the feed size. For large industrial jaw crushers, the feed size can be up to 1,000 mm, with an output size range of 0 to 200 mm. Laboratory-scale jaw crushers are much smaller, with feed sizes up to 200 mm and final sizes as fine as 1-6 mm.

Several key factors affect the final particle size and the efficiency of the crushing process.

1. Jaw Crusher Design and Specifications:

Size of the Crusher: Larger jaw crushers generally produce larger output particle sizes.

Jaw Plate Design: The profile and material of the jaw plates (e.g., corrugated, smooth) impact the crushing action and the resulting particle size.

Toggle Plate Setting (Closed Side Setting - CSS): This is the most crucial factor. The CSS refers to the minimum gap between the fixed and movable jaw at the discharge opening. A smaller CSS results in finer output, while a larger CSS yields coarser material.

Angle of Nip: The angle at which the material is "nipped" between the jaws affects crushing efficiency and particle size.

Eccentric Throw: The distance the movable jaw travels also plays a role in the crushing action.

2. Material Properties:

Hardness and Abrasiveness: Harder and more abrasive materials require more crushing force and can lead to faster wear on jaw plates, potentially affecting particle size consistency over time.

Toughness: Tough materials resist fracture and may require more passes or a tighter CSS to achieve the desired particle size.

Moisture Content: High moisture can cause material to stick together, leading to clogging and inconsistent particle sizing.

Feed Size Distribution: The size of the material being fed into the crusher (feed size) directly influences the output particle size. If the feed is too large, it may not be properly crushed.

Shape of Feed Material: Irregularly shaped feed can sometimes lead to bridging or inconsistent crushing.

3. Operating Conditions:

Feed Rate: Overloading the crusher with too high a feed rate can lead to reduced efficiency and a coarser product, as material doesn't have enough time to be properly crushed.

...

For more detailed information about the crushing size range of jaw crusher and its influencing factors, please click here: https://www.yd-crusher.com/a/news/particle-size-range-of-jaw-crusher.html